- Brake Pad

- Premium Aftermarket Parts

- You'll find all products from our current inventory in our online catalog

- One year guarantee

- Download

- Brake disc

- Premium Aftermarket Parts

- You'll find all products from our current inventory in our online catalog

- One year guarantee

- Download

- Shock Absorber

- Premium Aftermarket Parts

- You'll find all products from our current inventory in our online catalog

- One year guarantee

- Download

THE OFFICIAL PAGE OF GENESSO

The Automotive Aftermarket division (AA) provides the aftermarket and repair shops worldwide with a complete range of diagnostic and repair shop equipment and a wide range of spare parts.

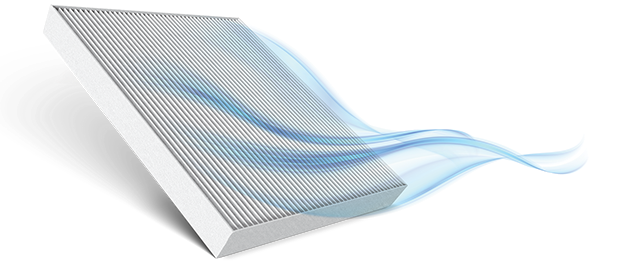

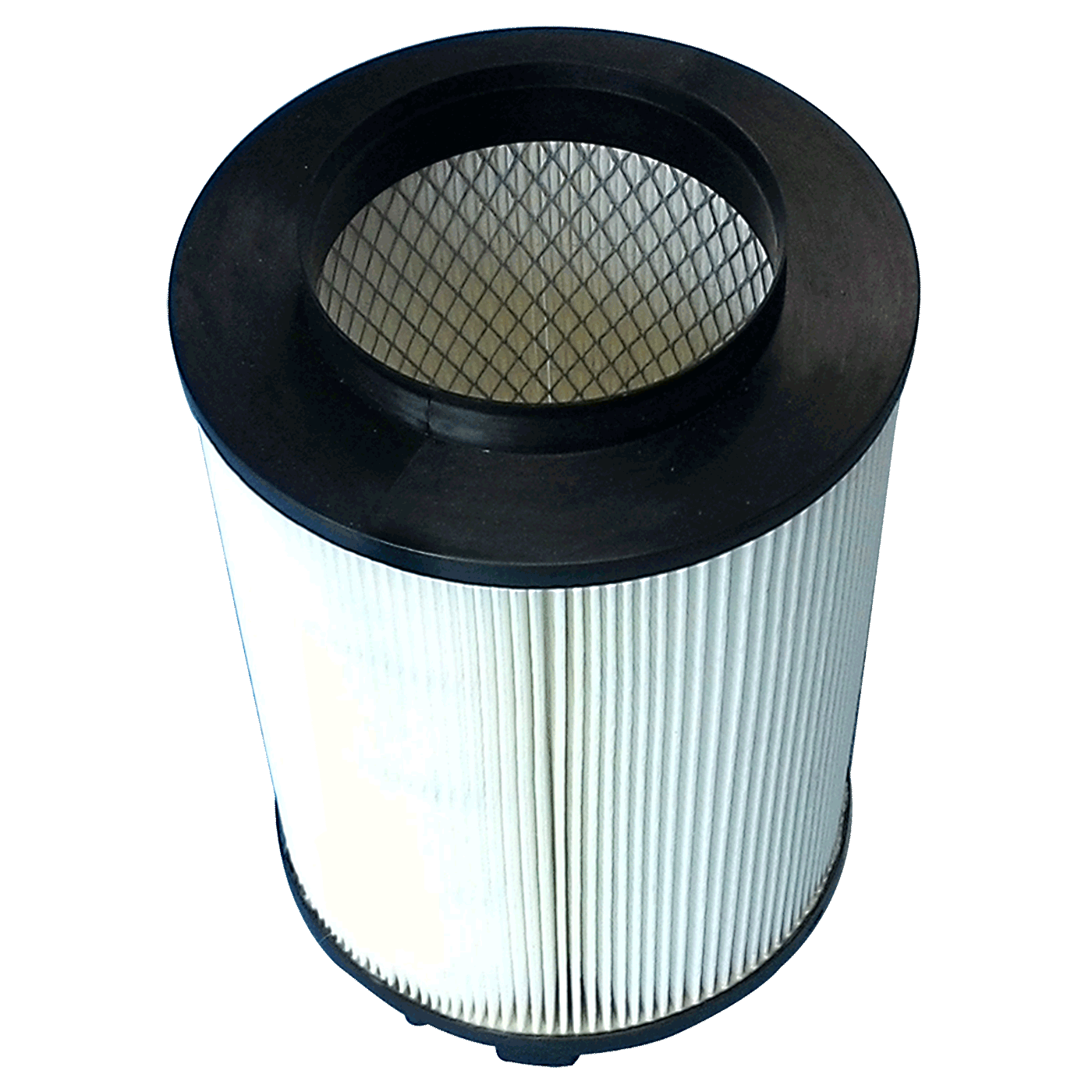

Genesso Air Filter

Genesso Air Filter

A particulate air filter is a device composed of fibrous materials which removes solid particulates such as dust, pollen, mould, and bacteria from the air. Filters containing an absorbent or catalyst such as charcoal (carbon) may also remove odors and gaseous pollutants such as volatile organic compounds or ozone. Air filters are used in applications where air quality is important, notably in building ventilation systems and in engines.

Some buildings, as well as aircraft and other human-made environments (e.g., satellites and space shuttles) use foam, pleated paper, or spun fiberglass filter elements. Another method, air ionisers, use fibers or elements with a static electric charge, which attract dust particles. The air intakes of internal combustion engines and air compressors tend to use either paper, foam, or cotton filters. Oil bath filters have fallen out of favor. The technology of air intake filters of gas turbines has improved significantly in recent years, due to improvements in the aerodynamics and fluid dynamics of the air-compressor part of the gas turbines.

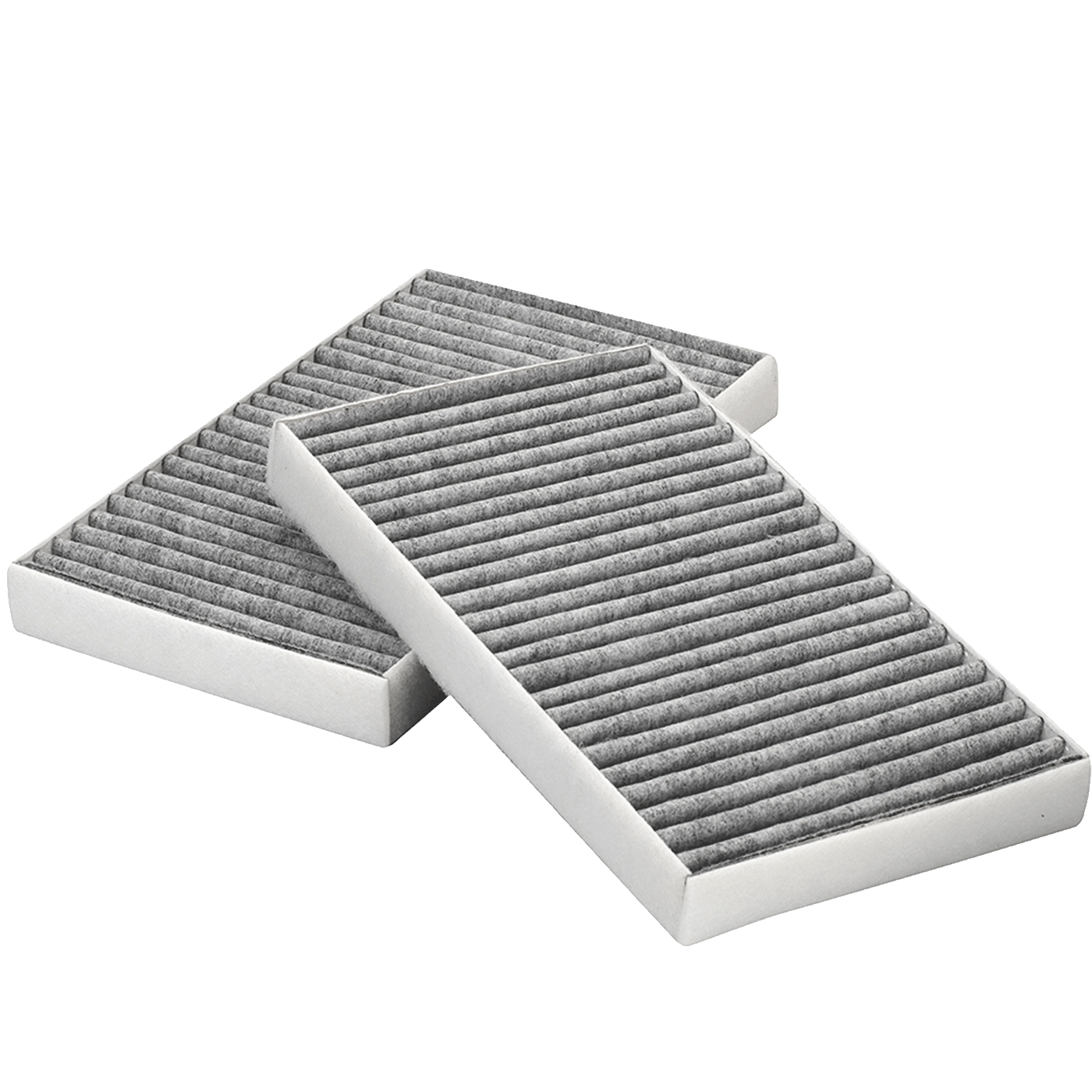

Genesso Cabin Filter

Genesso Cabin Filter

The internal combustion engine in most cars and trucks is cooled by a water and antifreeze mixture that is circulated through the engine and radiator by a water pump to enable the radiator to give off engine heat to the atmosphere. Some of that water can be diverted through the heater core to give some engine heat to the cabin, or adjust the temperature of the conditioned air.

A heater core is a small radiator located under the dashboard of the vehicle, and it consists of conductive aluminium or brass tubing with cooling fins to increase surface area. Hot coolant passing through the heater core gives off heat before returning to the engine cooling circuit.

The squirrel cage fan of the vehicle's ventilation system forces air through the heater core to transfer heat from the coolant to the cabin air, which is directed into the vehicle through vents at various points.

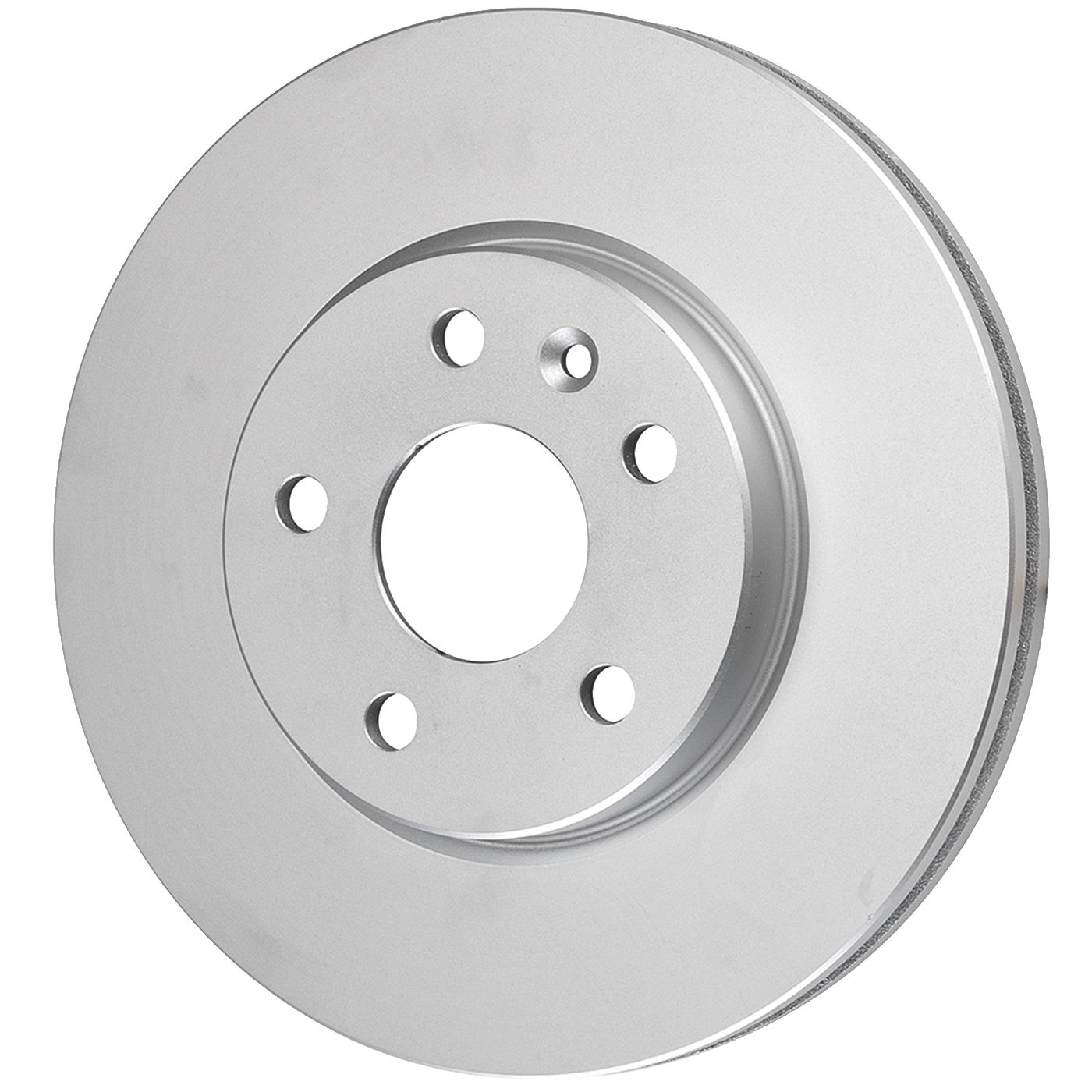

Genesso Brake Disc

Genesso Brake Disc

For automotive use, disc brake discs are commonly manufactured out of a material called grey iron. The SAE maintains a specification for the manufacture of grey iron for various applications. For normal car and light-truck applications, SAE specification J431 G3000 (superseded to G10) dictates the correct range of hardness, chemical composition, tensile strength, and other properties necessary for the intended use. Some racing cars and airplanes use brakes with carbon fiber discs and carbon fiber pads to reduce weight. Wear rates tend to be high, and braking may be poor or grabby until the brake is hot.

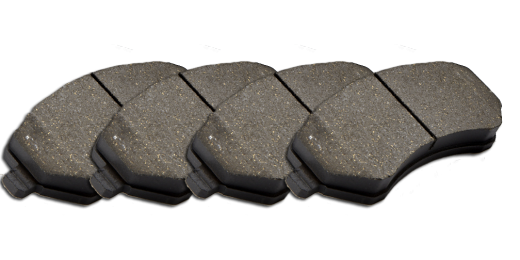

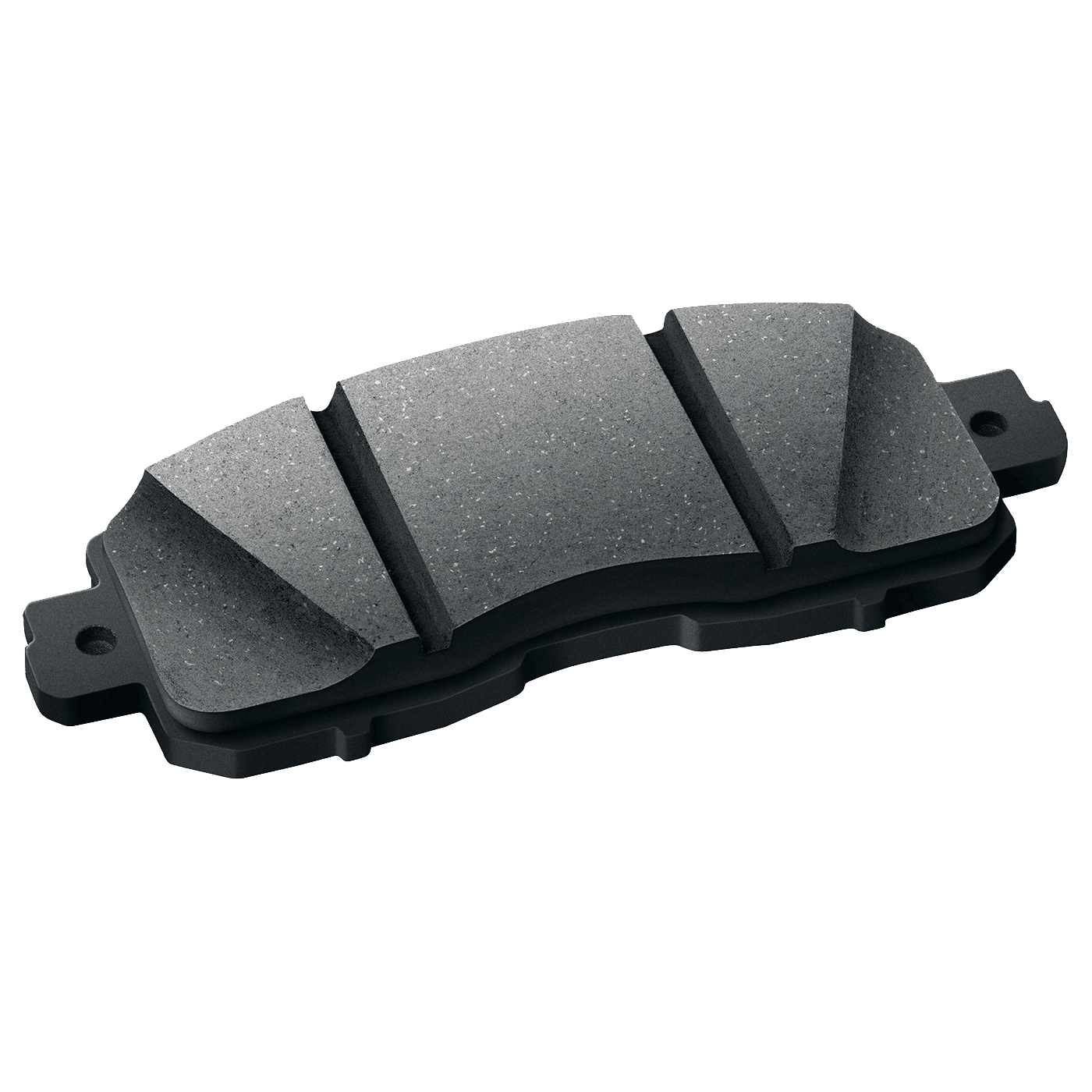

Genesso Brake Pad

Genesso Brake Pad

Brake pads are a component of disc brakes used in automotive and other applications. Brake pads are steel backing plates with friction material bound to the surface that faces the disc brake rotor.

Brake pads convert the kinetic energy of the vehicle to thermal energy through friction. Two brake pads are contained in the brake caliper, with their friction surfaces facing the rotor. When the brakes are hydraulically applied, the caliper clamps or squeezes the two pads together onto the spinning rotor to slow/stop the vehicle. When a brake pad heats up due to contact with the rotor, it transfers small amounts of its friction material onto the disc, leaving a dull grey coating on it. The brake pad and disc (both now having the friction material), then "stick" to each other, providing the friction that stops the vehicle.

In disc brakes, there are usually two brake pads per disc rotor. These are held in place and actuated by a caliper affixed to the wheel hub or suspension upright. Most vehicles have two brake pads per caliper. However racing calipers can utilize up to six pads, with varying frictional properties in a staggered pattern for optimum performance. Depending on the properties of the material, disc wear rates may vary. The brake pads must usually be replaced regularly (depending on pad material) to prevent brake fade. Most brake pads are equipped with a method of alerting the driver when this needs to be done. A common technique is manufacturing a small central groove whose eventual disappearance by wear indicates the end of a pad's service life. Other methods include placing a thin strip of soft metal in a groove, such that when exposed (due to wear) the brakes squeal audibly and embedding a soft metal tab in the pad material that closes an electric circuit and lights a dashboard warning light when the brake pad wears thin.

Genesso CV Joint

Genesso CV Joint

Constant-velocity joints (also known as homokinetic or CV joints) allow a drive shaft to transmit power through a variable angle, at constant rotational speed, without an appreciable increase in friction or play. They are mainly used in front wheel drive vehicles, and many modern rear wheel drive cars with independent rear suspension typically use CV joints at the ends of the rear axle halfshafts and increasingly use them on the drive shafts.

Constant-velocity joints are protected by a rubber boot, a CV gaiter, usually filled with molybdenum disulfide grease. Cracks and splits in the boot will allow contaminants in, which would cause the joint to wear quickly.

Genesso Wheel Bearing

Genesso Wheel Bearing

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the plain bearing, consists of a shaft rotating in a hole. Lubrication is often used to reduce friction. In the ball bearing and roller bearing, to prevent sliding friction, rolling elements such as rollers or balls with a circular cross-section are located between the races or journals of the bearing assembly. A wide variety of bearing designs exists to allow the demands of the application to be correctly met for maximum efficiency, reliability, durability and performance.

Genesso Hub Assy

Genesso Hub Assy

A wheel hub assembly (WHA), also referred to as hub assembly, wheel hub unit, wheel hub bearing, etc., is an automotive part used in most cars, passenger vehicles and light and heavy trucks.

It is located between the brake drums or discs and the drive axle. On the axle side, it is mounted to the holding bracket from the chassis; on the disc side, the wheel is mounted to the bolts of the WHA. When replacing, a wheel hub assembly should be torqued to the vehicle's specifications to prevent failure.

Genesso Shock Absorber

Genesso Shock Absorber

A shock absorber (in reality, a shock "damper") is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot.

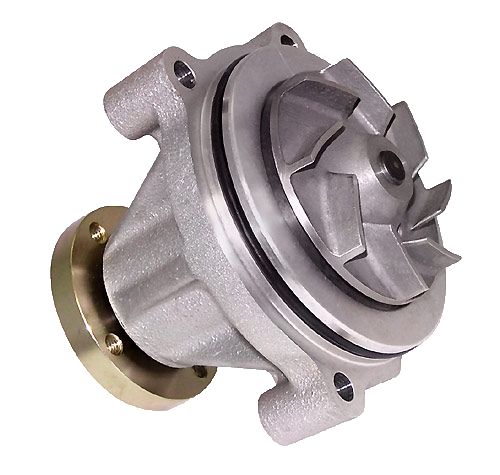

Genesso Water Pump

Genesso Water Pump

Water cooling is a method of heat removal from components and industrial equipment. As opposed to air cooling, water is used as the heat conductor. Water cooling is commonly used for cooling automobile internal combustion engines and large industrial facilities such as steam electric power plants, hydroelectric generators, petroleum refineries and chemical plants. Other uses include cooling the barrels of machine guns, cooling of lubricant oil in pumps; for cooling purposes in heat exchangers; cooling products from tanks or columns, and recently, cooling of various major components inside high-end personal computers such as CPUs, GPUs, and motherboards. The main mechanism for water cooling is convective heat transfer.

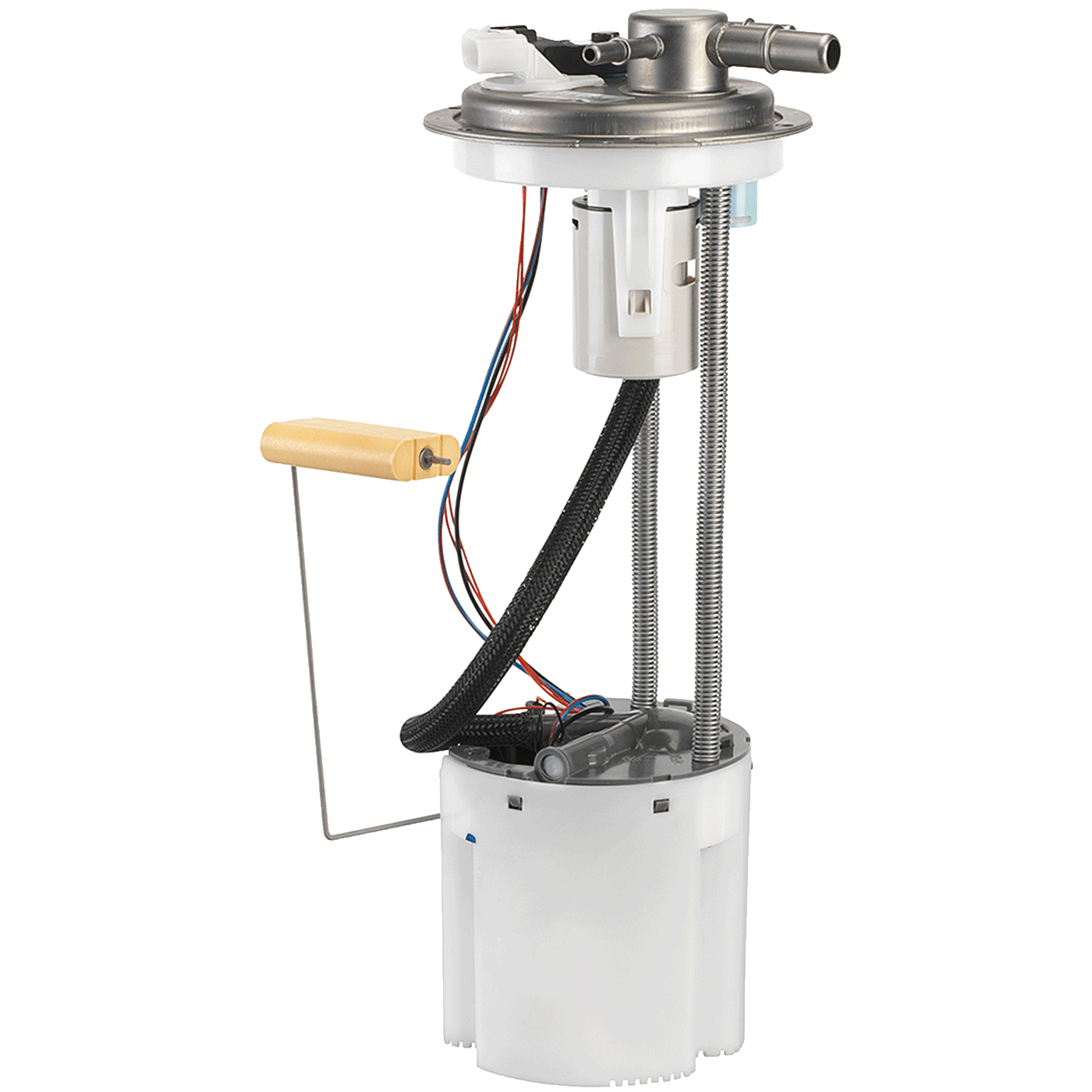

Genesso Fuel Pump Assy

Genesso Fuel Pump Assy

Genesso Fuel Pump

Genesso Fuel Pump

Genesso Fuel Pump

Genesso Fuel Pump

Genesso Fuel Filters

Genesso Fuel Filters

Line Chart

Sales Bar Chart

Genesso Pie Chart

Contact us

Mail

info@genesso.net

About

Cars commercial vehicles are the activities of Genesso Group.

Quality, Safety and Environment Policy.

Genesso Premium Aftermarket Parts

Copyright ©

2018

Genesso